ChipQuik 58°C low melt solder will easily remove SMD parts , preventing damage to the PCB by not using excessive heat. Removing SMD Integrated Circuits ,USB and HDMI connectors is a quick and easy process using this low melt solder.

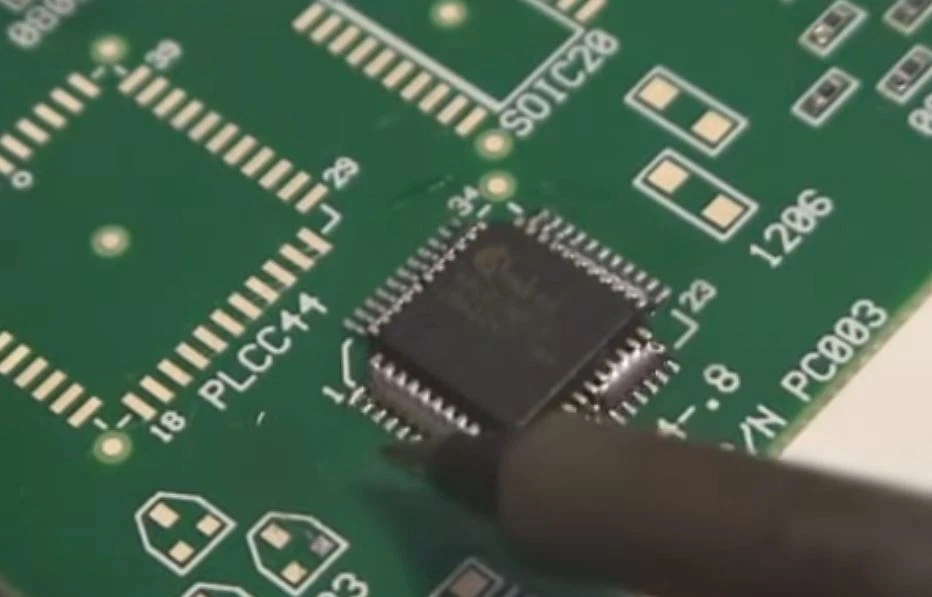

Apply the low melt solder to the integrated circuit or connector pins as the existing lead free solder melts the low melt solder will flow into the joint and mix with the lead free lowering its melting temperature considerably. At this point the solder will remain molten on all pins of the device, at which point the chip or connector can be gently lifted off the PCB.

Once the chip or connector is removed the pads will need cleaning by removing the excess low melt solder with solder braid (Braid Wick). This is to prevent brittle solder joints when fresh leaded 180°C solder is added. After soldering clean the flux of the PCB area soldered with 99.9% Isopropyl Alcohol. We also recommend cleaning any low melt of the soldering iron tip and reapply some leaded solder o extend tip life.

ChipQuik 58°C low melt solder sold as 1 x 15cm stick.

ChipQuik Low Melt Solder Specs:

- Melting temperature 58°C

- Supplied as a 6.5″ (15cm) length stick

- Flux type: No Clean

- Flux classification: RELO